The difference between new energy transmission fluid and traditional transmission fluid

With the rapid development of new energy vehicles, specialized transmission fluid (EV Transmission Fluid) has gradually diverged from traditional gasoline vehicle transmission fluid. Although both are lubricants for transmission systems, they differ significantly in terms of base oil, additives, performance requirements, and application scenarios.

1. Base oil and viscosity characteristic

New energy gearbox oil: Generally uses fully synthetic base oil, suitable for high speeds (12,000–20,000 rpm) and high temperature conditions. Lower viscosity (such as 0W-20) to reduce friction loss and improve vehicle range.

Conventional Transmission Fluid: Some still use semi-synthetic or mineral oils with higher viscosity (e.g., ATF/CVT oil), prioritizing smooth shifting and hydraulic system performance.

2. Additives and electrical compatibility

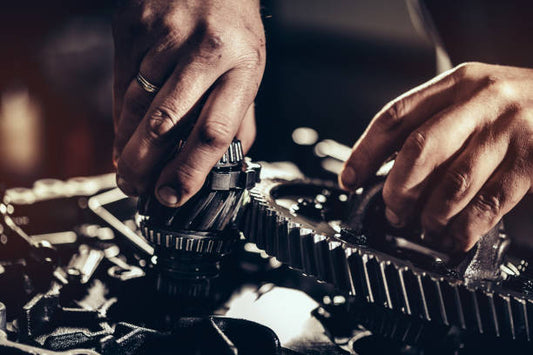

New energy oil: Requires the addition of anti-electrocorrosion agents and low electrical conductivity formulations to prevent conductive impurities from causing motor short circuits. At the same time, anti-oxidation and anti-wear additives are strengthened to cope with high-temperature, high-load gear meshing.

Traditional oil: No electrical compatibility requirements. Additives are mainly targeted at anti-wear, anti-oxidation, and friction regulation to ensure the normal operation of the clutch and hydraulic system.

3. Core performance requirement

New Energy Transmission Oil:

Electrical Insulation: Low electrical conductivity ensures the safety of motors and electronic components.

High-temperature stability: Withstands temperatures above 150°C to prevent motor demagnetization.

Friction characteristics: Low friction to enhance efficiency while maintaining high load-bearing capacity to protect gears and bearings.

Conventional transmission oil:

Emphasizes smooth shifting and friction regulation (e.g., CVT oil prevents chain slippage).

Operating temperature typically below 120°C with lower heat dissipation pressure.

4. Differences in application scenario

Hybrid Electric Vehicles (HEV/PHEV): The fluid must accommodate both engine and motor operating conditions, withstand frequent switching (DHT system), and meet wide temperature range (-40°C to 170°C) and shear resistance requirements.

Electric Vehicles (EV): The transmission lacks engine residual heat assistance, so the fluid must have stronger active cooling performance and be compatible with motor bearing grease.

Conventional Internal Combustion Engine Vehicles: Automatic transmissions require specific friction coefficients to ensure smooth shifting; manual transmissions prioritize gear protection.

5. Replacement cycle

New energy transmission fluid: It is recommended to replace every 2 years or 40,000 kilometers (depending on the vehicle model and operating conditions), as high-speed acceleration accelerates oil aging.

Conventional transmission fluid: ATF is typically replaced every 60,000–80,000 kilometers or 3–5 years; manual transmission fluid is replaced approximately every 40,000–60,000 kilometers.